Hard surface modeling supports clear, repeatable production steps that help your team avoid rework and maintain asset quality throughout a project. We follow a direct approach that focuses on strong geometry, predictable structure, and efficient handoff between modelers, artists, and developers.

Your company gains reliable output when every asset follows the same standards for scale, topology, and detail, so our experts keep the workflow transparent and easy to review. Production teams often face delays when models break during rigging, simulation, or rendering, so we remove those risks early through strict verification.

Our specialists rely on proven software and structured review methods to keep every part of the pipeline aligned with your goals. You receive assets that match technical limits, visual targets, and downstream requirements without guesswork. Many organizations work with a 3D modeling company to secure consistent results, and we apply the same clarity to every stage of hard surface modeling.

Our team focuses on accuracy, fast communication, and clean revisions. Your business can ship features, updates, or interactive products faster when the asset pipeline stays predictable. You receive a straightforward production flow built on stable methods rather than subjective interpretations.

What Is Hard Surface Modeling? Understanding Its Production Value

Hard surface modeling defines the structure and accuracy of most non-organic assets your production team depends on. Our specialists rely on consistent geometry rules that support fast review, clean revisions, and stable performance across multiple platforms. Many teams introduce delays when asset quality varies across models, so uniform standards help your project avoid unnecessary fixes.

Every decision around edges, shapes, and topology influences how your developers, artists, and technical teams handle the assets later in the pipeline. Strong coordination across all stages keeps your costs predictable and your timeline under control. Our work in 3D modeling for games often requires strict alignment between visual targets and performance budgets, so a clear method for hard surface modeling gives you control over both.

Your business gains practical value once every asset behaves reliably during animation, interaction, and rendering. Hard surface modeling becomes a direct contributor to stable production rather than an isolated artistic task.

Definition of Hard Surface 3D Modeling and Its Role in Modern Pipelines

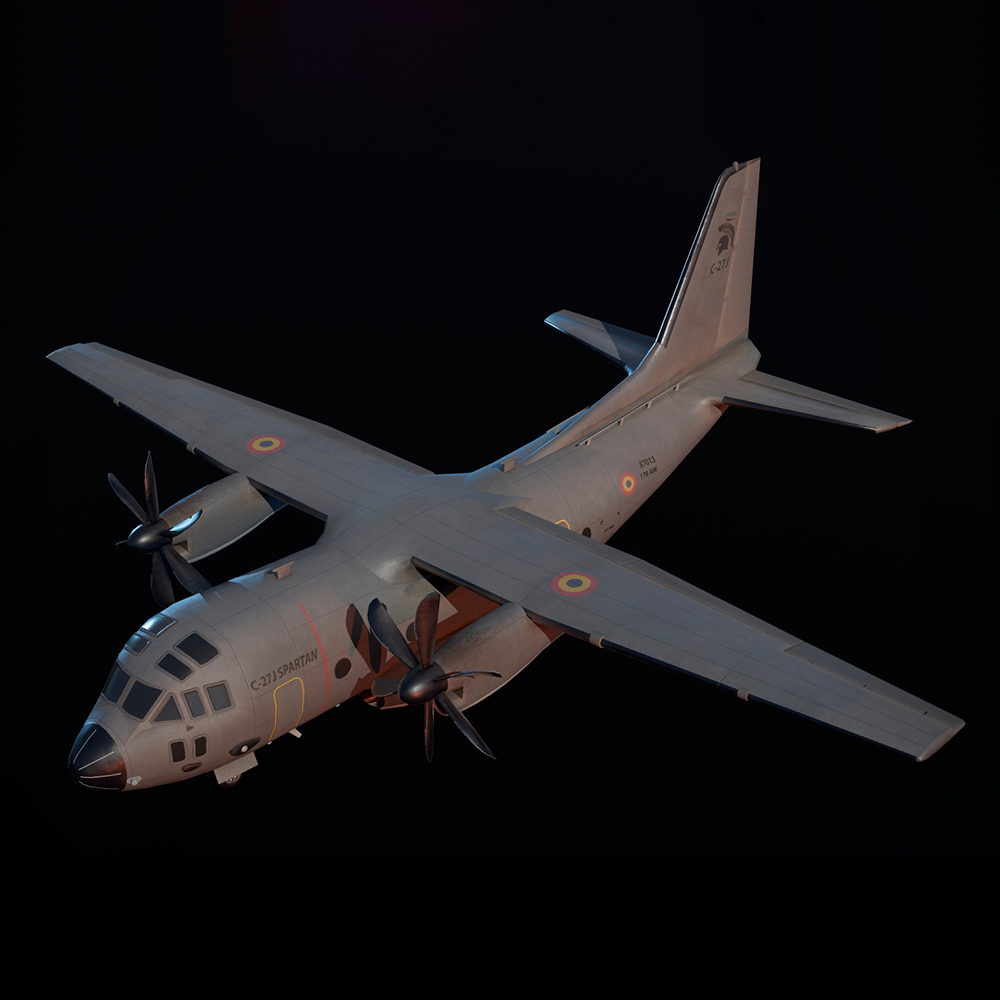

Hard surface 3D modeling focuses on objects with sharp features, defined contours, and mechanical structure. Your team works with assets such as tools, machines, vehicles, devices, and architectural elements that require predictable geometry.

Our experts prioritize precision because every bevel, supporting edge, or surface transition affects shading, collision, and simulation. Production teams gain stability when every model follows a uniform specification that reduces unexpected behavior in later stages.

A simple comparison helps your team see how both approaches differ in practice:

- Clear topology. Geometry follows a controlled flow that supports deformation or static use.

- Accurate scale. Measurements align with real values or project rules without corrections later.

- Predictable shading. Surface transitions respond correctly to lighting and material setups.

Our process builds clean models that integrate smoothly into any stage of your pipeline. You avoid last-minute fixes, and your developers receive assets ready for direct use. Our 3D props modeling practice relies on standards that help your organization maintain quality even under tight deadlines.

Distinguishing Hard Surface Modeling from Organic Techniques

Hard surface modeling focuses on rigid forms, while organic modeling supports characters, creatures, foliage, and irregular natural shapes. Your production team must treat these categories separately because each one requires different tools, topology rules, and review criteria.

Hard surface assets benefit from sharp transitions, controlled edges, and structural logic, while organic assets rely on curvature, deformation flow, and anatomical consistency. Mixing both methods without clear separation often creates shading issues, unpredictable silhouettes, or performance loss.

A short breakdown of common scenarios makes the role of hard surface modeling easier to evaluate:

- Form priority. Hard surface assets rely on precision; organic assets rely on fluid shape.

- Topology rules. Hard surface geometry stays controlled; organic geometry follows deformation lines.

- Detail logic. Hard surface detail supports mechanical behavior; organic detail reflects biological variation.

- Production impact. Hard surface mistakes often cause lighting errors; organic mistakes cause deformation issues.

Your team benefits from clear boundaries between these workflows, especially when assets must move through several departments. Our specialists apply polygonal and spline modeling methods only when each technique fits the asset structure, not as a universal approach. Strong separation keeps the pipeline efficient.

Typical Use Cases Where Hard Surface Modeling Impacts Project Efficiency

Hard surface modeling supports many production scenarios where consistency, speed, and accuracy directly influence delivery. Your organization gains reliable outcomes once the workflow aligns with both visual and technical requirements. Many interactive products, simulations, and commercial projects depend on precise geometry that behaves correctly under real conditions.

A short breakdown of common scenarios makes the role of hard surface modeling easier to evaluate:

- Mechanical products. Machines, tools, industrial devices, and equipment require strict accuracy.

- Architectural elements. Doors, panels, interiors, exteriors, and structural parts depend on a clean scale.

- Vehicles and transport. Cars, aircraft, drones, and machinery demand predictable shading and modular parts.

Three additional scenarios add clarity:

- Training simulations. Hard surface assets ensure consistent collision and reliable user interaction.

- Product visualization. Marketing and engineering teams receive accurate models for presentation and review.

- Game environments. Props, weapons, and technical objects maintain visual consistency across levels.

Your pipeline gains measurable efficiency when teams depend on assets built with hard surface standards. Our specialists apply controlled methods that support predictable outcomes without unnecessary revisions.

Team up with professional 3D modeling studio. Contact our team!

Why Hard Surface Modeling Matters for Scalable Digital Production

Hard surface modeling gives your project a stable foundation that supports fast production, clean revisions, and predictable integration. Our team focuses on structure, scale accuracy, and surface control because those elements determine how smoothly your developers and artists can work with the final assets.

Your project benefits from clear rules that guide shape, complexity, and shading behavior across the entire library. Many teams ask how to make realistic 3D models that remain efficient under strict deadlines, and the answer often starts with strong modeling standards. Your business gains steady output once every model follows the same logic from draft to delivery.

How Accurate Assets Reduce Delays in Engineering, Simulation, and Product Visualization

Accurate geometry shapes how smoothly your engineers, artists, and simulation specialists progress through their work. Small issues, such as incorrect scale, uneven edges, or misplaced details, can delay testing or integration once assets reach those stages. A weapon 3D model highlights this easily because one wrong measurement can break collision, distort lighting, or disrupt animation flow.

Precision at the modeling stage protects your schedule and reduces the need for emergency fixes. Your team gains more predictable timelines when models enter the pipeline already aligned with technical requirements. Production becomes easier to manage when shading, proportions, and structure behave as intended.

The main areas where accuracy prevents delays include:

- Scale precision. Reliable proportions reduce the need for repeated adjustments across engines and tools.

- Structural alignment. Parts connect, rotate, and move without gaps or overlapping surfaces.

- Shading behavior. Surface transitions respond correctly to lighting and reflections.

Your team works faster when assets pass early checks without surprises, supporting cleaner reviews and more dependable handoffs between departments.

Consistency Requirements for Long-Term Asset Maintenance

Long-term production relies on asset libraries that stay organized, predictable, and easy to update. Your team works faster when older models follow the same structure as the new ones, allowing clean reuse instead of costly corrections.

Clear naming, controlled topology, and consistent version logic prevent confusion as your project grows, expands across platforms, or undergoes redesigns. Strong structure at the start keeps your library useful instead of turning into a source of delays.

Core areas where consistency supports long-term maintenance include:

- Naming clarity. Stable, readable labels help your team identify components quickly, reduce search time, and support smooth onboarding for new contributors.

- Geometry structure. Controlled topology avoids shading shifts, UV stretching, or breakage as rendering tools and engines evolve.

- Version alignment. Updates follow a clean chain rather than creating duplicate branches or outdated variations that slow down reviews.

- Texture stability. UVs and material assignments remain compatible when your team upgrades resolution, changes shaders, or improves visual targets.

Your project gains reliability when every asset remains maintainable across updates. Teams spend less time fixing legacy content and more time building new features, new visuals, and new interactive elements that drive forward progress.

How Stable Modeling Standards Support Faster Iterations

Iteration speed increases when your models respond well to adjustments and do not break under minor edits. Designers refine shapes more confidently, and developers test interactions without delays caused by distortion or shading faults.

Strong standards keep the structure predictable, so your team can react to feedback, explore new options, or replace outdated elements without falling into technical issues. A stable approach supports clearer planning and reduces stress during demanding production cycles.

The essential advantages that stable standards bring to iterative work include:

- Predictable changes. Edits stay controlled, prevent surface disruption, avoid flipped normals, and maintain correct silhouettes under all lighting conditions.

- Smoother collaboration. Artists, modelers, and developers rely on the same expectations for edge flow, density, naming, and organization, reducing handoff problems.

- Faster approvals. Reviewers face fewer technical surprises, shorten revision loops, and push assets through approval stages with far greater confidence.

Your team gains flexibility when modeling rules that support safe revisions. Projects reach stable versions sooner because every iteration delivers progress instead of new issues. A consistent structure gives you more room to experiment, improve ideas, and finalize updates at a steady, reliable pace.

What Is Hard Surface Modeling in a Real Production Context

Hard surface modeling in production focuses on building structured, predictable assets that support stable workflows across design, engineering, and real-time environments. Teams work with forms that require accuracy, sharp transitions, and dependable scale, so every modeling choice directly impacts performance and integration.

Consistent structure helps developers, artists, and technical specialists rely on the same visual and functional standards. A well-planned approach turns hard surface modeling into a practical tool that supports deadlines, revisions, and long-term asset reuse.

The Structural Principles Behind Hard Surface 3D Modeling

Hard surface assets depend on clear geometric intent, stable shapes, and edge control that remains consistent through all production stages. Your team gains efficiency when the structure follows logic that supports shading accuracy, clean deformation where needed, and predictable silhouette behavior.

Strict structural rules also help avoid technical issues that appear during lighting, collision setup, or simulation. Each model becomes easier to evaluate because its surfaces follow a readable pattern instead of irregular detail placement.

Foundational principles guiding structural decisions include:

- Controlled edges. Support edges define how surfaces hold sharpness under subdivision or smoothing.

- Stable forms. Large shapes carry the design, and secondary elements reinforce function without clutter.

- Topology logic. Flow supports curvature, avoids pinching, and keeps surface tension balanced.

- Scale reliability. Every measurement aligns with project rules rather than personal guesswork.

Your production pipeline benefits from models that communicate their structure clearly. Reviewers understand the intent, developers experience fewer technical surprises, and artists gain a strong base for material work, detailing, and optimization.

How Modularity, Reusability, and Clean Geometry Affect Operational Cost

Operational cost drops significantly when assets can be reused, combined, or modified without cleanup. Modularity helps your studio maintain a library that supports rapid assembly of scenes, props, and environments. Clean geometry also reduces the time spent fixing shading errors, irregular UVs, or unwanted intersections. Fewer corrections mean more time for creative decisions and less budget wasted on repetitive fixes.

A grouped comparison highlights where cost savings appear:

Modularity

- Faster assembly of complex objects.

- Easier creation of variations.

- Lower effort for testing new designs.

Reusability

- Existing assets support new features.

- Reduced modeling workload for sequels or expansions.

- More predictable planning across multi-phase projects.

Clean geometry

- UVs unwrap faster with fewer distortions.

- Shading remains stable across engines.

- Optimization requires less manual intervention.

Your organization benefits when assets follow a structure that supports repeat use instead of one-off creation. Clear modular thinking extends the lifespan of each asset and helps every department work with fewer interruptions.

Material and Shading Expectations Guiding Hard Surface Pipeline Decisions

Material and shading requirements influence many modeling decisions long before a surface receives textures. Your team gains better results when every model supports consistent highlights, reflections, and roughness behavior.

Surface transitions must remain clean because small geometric issues often become highly visible under metallic, glossy, or coated materials. Technical artists depend on predictable geometry to apply masks, decals, and wear patterns without distortion.

Main factors shaping material-related modeling choices include:

- Surface continuity. Smooth gradients need uninterrupted topology.

- Hard transitions. Sharp edges must support proper bevels to avoid broken reflections.

- UV strategy. Layouts must reduce stretching, seams, and mismatched texel density.

- Normal map support. Geometry must provide enough clarity for baked detail to read accurately.

Your pipeline gains visual consistency when modeling and shading teams follow the same expectations from the start. Hard surface models behave more reliably under demanding lighting setups, which improves visual quality while reducing the number of corrective passes.

Hard Surface Modeling Workflow — Production Stages Breakdown

Hard surface modeling follows a series of steps that keep the asset predictable from the first draft to the final export. Your project moves faster when each stage focuses on clear goals rather than scattered adjustments. Early structure defines how well the model behaves under materials, lighting, and engine constraints, while later passes add refinement without breaking earlier work.

Strong workflow organization also reduces the number of revisions your team faces during testing or review. A consistent sequence gives developers and artists the confidence to handle updates, variations, and new requirements without destabilizing the asset.

Blockout, Shape Exploration, and Constraint Planning for Reliable Scaling

Early modeling decisions shape everything that follows, so the blockout stage carries more responsibility than many teams realize. Your modelers define the fundamental proportions, silhouette, and functional intent before adding any detail. Shape exploration helps verify that the asset reads clearly at a distance, supports gameplay or simulation needs, and remains practical to animate or assemble.

Reliable scaling also depends on understanding real-world references, engine limitations, and any constraints set by designers or engineers. Strong planning at this stage prevents distortion later and protects the entire workflow from cascading issues.

Core elements that guide the blockout phase include:

- Primary forms. Large shapes establish the identity and function of the object.

- Secondary shapes. Supporting pieces reinforce purpose without adding unnecessary complexity.

- Scale checks. Measurements align with references and match the intended environment.

- Constraint mapping. Requirements from design, engineering, or gameplay guide each proportion.

Your team gains far more stability when the blockout supports clear goals. Later stages become faster because the base structure already carries the logic that the entire model depends on.

Mid-Detail Development, Topology Refinement, and Edge Control Techniques

Mid-detail development strengthens form definition without overwhelming the silhouette. Your team adds structural elements, functional cuts, and controlled bevels that support readability in all lighting conditions. Topology refinement also becomes essential at this stage because geometry flow affects how the surface handles curvature, shading, and potential deformation.

Edge control helps maintain sharpness where needed and smooth transitions where softer surfaces appear. A balanced approach keeps the model clean, efficient, and ready for downstream tasks such as material work and baking.

Important considerations during mid-detail refinement include:

- Flow stability. Edge loops follow the intended form and avoid sudden direction changes.

- Controlled beveling. Sharp features stay crisp without creating harsh artifacts.

- Density balance. Geometry increases only where visual value requires it.

- Transition logic. Surfaces shift smoothly between hard and soft areas.

Your model gains structural clarity once mid-detail work follows predictable rules. Departments relying on the asset experience fewer shading surprises, cleaner bakes, and more reliable integration into scenes or simulations.

Final Detailing, UV Strategy, and Model Validation for Export

Final detailing focuses on adding elements that improve realism without sacrificing efficiency. Your team introduces screws, vents, grooves, and functional accents that communicate real-world intent. UV strategy becomes critical because poor layouts lead to stretching, inconsistent texel density, or visible seams.

A clean unwrap ensures your material artists can apply masks, decals, and wear patterns accurately. Model validation completes the process by checking scale, topology, naming rules, and export settings before handing the asset to downstream departments.

Key factors defining the final stage include:

- Detail restraint. Add only what improves readability and purpose.

- UV clarity. Layouts avoid distortion and preserve consistent density.

- Bake readiness. Surfaces support clean normal, AO, and curvature outputs.

- Export checks. Naming, orientation, and units match pipeline requirements.

Your production becomes more reliable when each asset passes validation before advancing to the next stage. Strong final steps remove uncertainty, limit revision cycles, and keep your team focused on delivering stable, ready-to-use models.

Technical Foundations of Hard Surface 3D Modeling and Why They Matter

Technical choices in hard surface modeling influence how well an asset performs once it enters animation, simulation, or a game engine. Your team depends on predictable geometry that supports shading, collision, and efficient rendering across multiple platforms. Strong modeling standards help avoid surprise artifacts, unstable silhouettes, and excessive processing cost.

For instance, many teams working on Roblox 3D modeling or large real-time projects benefit from foundations that keep assets clean and manageable. Clear rules for topology, subdivision, and optimization provide every department with a stable foundation for further work, reducing the risk of errors during integration or review.

Topology Rules That Ensure Predictable Behavior in Animation and Simulation

Topology defines how a model behaves once it enters movement, physics, or any form of simulation. Your team needs geometry that supports clear edge flow, even surface tension, and reliable deformation around joints or mechanical pivots.

Controlled topology also prevents shading issues that often appear on hard surfaces when edges pinch, stretch, or break under stress. Clean structure gives your developers and artists confidence that the asset will behave correctly long after modeling is finished.

Core topology requirements that support predictable behavior include:

- Even distribution. Faces maintain balanced spacing to avoid sudden deformation spikes.

- Logical flow. Edge loops follow functional paths around hinges, pivots, or structural curves.

- Minimal poles. Fewer high-valence vertices reduce shading problems and unpredictable tension.

- Clean intersections. Merged geometry avoids hidden gaps or overlapping surfaces that break during animation.

Your pipeline stays stable when every model follows these rules. Simulation results become more reliable, and review cycles shrink because assets avoid the common technical issues that usually slow down animation or physics testing.

Subdivision, Boolean Workflows, and Non-Destructive Methods for Faster Edits

Subdivision and Boolean workflows give your team powerful tools for exploring form and adding complexity without committing too early. Non-destructive techniques help artists refine shapes repeatedly without rebuilding pieces from scratch.

Many production pipelines lean on these methods to test variations, adjust proportions, or experiment with detail placement while keeping the base structure intact. Your project benefits from flexible modeling choices that support quick changes late in development.

The primary advantages of these workflows include:

- Subdivision control. Smooth surfaces remain consistent while supporting defined edges through support loops or crease settings.

- Boolean flexibility. Complex cuts, panel lines, and inserts form quickly without heavy manual modeling.

- Non-destructive stacks. Modifiers allow repeated adjustments without damaging the core mesh.

- Rapid iteration. Artists test multiple ideas while preserving full reversibility.

Your team avoids unnecessary rebuilds when these methods guide early and mid-stage work. The asset stays adaptable, and updates remain efficient even when direction shifts or feedback from reviewers requires rapid changes.

Maintaining Performance Targets Through LODs and Geometry Optimization

Performance targets dictate how much geometry detail your project can afford. Real-time engines depend on assets that scale correctly across hardware tiers, camera distances, and scene complexity. LODs also play a major role by giving the engine lower-cost versions of the model at distances where detail is less visible.

Main techniques that support strong performance include:

- Controlled density. Geometry adds detail only where readability demands it.

- LOD hierarchy. Progressive versions reduce complexity smoothly across distance thresholds.

- Clean normals. Correct smoothing and normal maps preserve detail without unnecessary polygons.

- Efficient silhouettes. Shape clarity guides optimization so reductions avoid visual collapse.

Your team gains predictable rendering behavior once optimization becomes a deliberate part of the modeling process. Assets load faster, run smoother, and maintain stable performance even in heavy scenes or large multiplayer environments.

Quality Assurance Metrics for Hard Surface Modeling Deliverables

Quality assurance in hard surface modeling focuses on verifying accuracy, structural logic, and reliable behavior across engines and workflows. Your team depends on assets that meet technical expectations and behave predictably under lighting, animation, and simulation. Strong QA procedures reduce rework, improve clarity, and keep deadlines stable. Many studios use polygonal 3D modeling techniques to maintain clean geometry and consistent standards across large asset libraries. A clear QA system keeps artists, developers, and technical reviewers aligned while limiting unexpected issues in later stages.

Geometry Accuracy, Scale Verification, and Alignment with Technical Specs

Geometry accuracy ensures that every detail respects real measurements, functional intent, and the constraints of your project. Scale verification allows developers to rely on predictable proportions across scenes, tools, and pipelines. Alignment with technical specifications also prevents issues that appear during rigging, simulation, or assembly. Reliable QA at this level protects production by detecting errors before they reach downstream departments.

Important accuracy checks include:

- Scale matching. Measurements align with references and maintain proportional consistency in the target engine.

- Functional alignment. Hinges, pivots, and mechanical elements follow expected dimensions.

- Surface continuity. Curves, flats, and transitions remain smooth without irregular tension.

- Deviation control. Edges and bevels maintain intended width and do not drift during edits.

Your team benefits from assets that pass these checks early, leading to faster iteration and cleaner integration across all departments. Predictable geometry becomes a foundation for stronger collaboration and more stable production schedules.

Model Cleanliness, UV Efficiency, and Error Prevention Checklists

Clean models reduce shading artifacts, save time in material creation, and minimize issues during export. UV efficiency ensures that texture detail remains consistent, predictable, and distortion-free. A structured error-prevention checklist helps teams avoid problems that commonly disrupt production. A hybrid format works well in this section: a brief explanation followed by a compact table that groups key criteria.

Core Quality Dimensions

| Area | What To Check | Why It Matters |

| Topology clarity | No stray vertices, hidden faces, or ngons. | Keeps shading stable and supports clean bakes. |

| UV layout | Even texel density, minimal stretching, logical islands. | Improves texture readability and material accuracy. |

| Normals | Correct smoothing, no flipped faces. | Prevents lighting artifacts and shading errors. |

| Error flags | No overlapping geometry, no open edges unless intentional. | Reduces engine warnings and export failures. |

Your production flow stays smooth when each model meets these expectations before reaching lighting, rigging, or engine integration. Clean work habits lower the likelihood of costly fixes later and give material artists and developers a reliable foundation.

Review Processes That Reduce Rework for Cross-Disciplinary Teams

Cross-disciplinary teams rely on consistent review methods to avoid miscommunication and late-stage revisions. Artists, developers, and technical specialists need a shared understanding of what defines a complete, valid asset. Early reviews catch structural issues quickly, while later reviews focus on final adjustments, naming clarity, or optimization requirements. A layered process gives every discipline a clear role without slowing progress.

A structured multi-stage workflow often delivers strong results:

- Structural review. Base forms, proportions, and topology logic get validated before detail work begins.

- Functional review. Mechanical intent, alignment for animation, and collision expectations get confirmed.

- Shading review. Surface flow, smoothing groups, and UV readiness get checked for material compatibility.

- Final technical review. Export settings, naming rules, orientation, and LOD setup receive a final sign-off.

Your project gains momentum when every discipline contributes at the right stage instead of reacting late in development. Predictable review cycles reduce rework, support clearer communication, and protect delivery timelines.

Integrating Hard Surface Modeling into Broader Production Ecosystems

Hard surface modeling is used in many pipelines, where accuracy and reliability affect multiple departments. Teams working on XR tools, interactive training, game development, or large simulation systems depend on assets that behave consistently across engines and hardware tiers.

Strong integration practices help avoid mismatches in scale, shading, and performance when assets move between stages. Clear rules around structure, naming, and optimization keep each department aligned. Your project delivers predictable results when hard surface modeling functions as an integrated part of the ecosystem rather than an isolated step.

How Hard Surface Assets Support XR, Gaming, Training, and Simulation Outputs

Hard surface assets appear across a wide range of digital environments, each with its own constraints. XR products demand low latency, readable silhouettes, and predictable shading. Game engines require balanced performance and strong LOD structures.

Training platforms rely on functional accuracy, in which objects behave correctly during scripted interactions. Simulation tools require precise geometry that supports physics, collision systems, and mechanical behavior.

The primary areas where hard surface models influence output include:

- Performance stability. Efficient geometry supports smooth rendering across VR, AR, and real-time engines.

- Interaction quality. Accurate pivots, collision shapes, and proportions improve usability in training and simulation.

- Visual consistency. Clean surfaces align with lighting and material systems across multiple output formats.

- Reliability across platforms. Assets maintain function whether deployed on headsets, desktops, or mobile devices.

The pipeline benefits when hard surface modeling accounts for these technical demands early, preventing costly fixes later in the asset lifecycle.

Asset Libraries, Version Control, and Long-Term Maintenance Strategies

Large productions grow quickly, and asset libraries become difficult to manage without structure. Teams gain long-term efficiency when version control systems track changes clearly and prevent conflicting edits. Maintenance strategies help avoid outdated geometry, duplicated files, or missing dependencies. A stable system ensures that artists and developers always work with verified, approved assets rather than manually sorting through old files.

Let’s review the core elements that strong asset management:

| Area | Practical Focus | Benefit |

| Library structure | Organized folders, naming rules, unified categories | Faster search and reuse |

| Version control | Clear commit messages, branching rules, permissions | Fewer file conflicts |

| Metadata | Scale notes, material IDs, export settings | Reliable handoff to other teams |

| Lifecycle management | Flags for outdated or superseded models | Clean, functional asset catalog |

Collaboration Frameworks That Connect Modelers, Tech Artists, and Developers

Collaboration shapes how fast a project progresses. Modelers focus on structure, tech artists check shading and engine behavior, and developers integrate assets into interaction systems. Clear frameworks help everyone understand where their responsibilities begin and end. Regular alignment prevents issues such as inconsistent scale, mismatched naming, or geometry incompatibilities that disrupt the pipeline.

A strong collaboration system often includes:

- Shared guidelines. Teams follow the same rules for topology, naming, and material IDs.

- Review checkpoints. Early and mid-stage reviews catch mistakes before they repeat across iterations.

- Direct communication channels. Fast feedback loops resolve issues before they stall development.

- Unified documentation. Teams reference a single source of truth for workflow expectations.

Your production gains momentum when specialists understand how their work fits into the larger system. Predictable collaboration reduces delays, supports cleaner asset flow, and helps everyone work toward the same technical goals.

Outsourcing and Team Extension Considerations for Hard Surface 3D Modeling

Outsourcing or expanding your internal team can relieve pressure on busy production cycles, especially when your deadlines require predictable output. Many studios turn to external specialists when the workload grows faster than internal capacity. Strong collaboration with external teams helps you maintain quality while meeting delivery goals. Outsourced support also helps maintain momentum when you need specific skills, faster turnaround, or additional flexibility. A structured approach to external work ensures that assets remain compatible with your pipeline, standards, and long-term plans.

When External Expertise Reduces Production Bottlenecks

Production slows down for many reasons: overlapping tasks, limited staff availability, or sudden requests for complex assets. An outside group can step in and take over a portion of the workload without requiring a long onboarding period. Large batches of props, mechanical parts, or detailed environment pieces often fit well within outsourced responsibilities, since internal artists can stay focused on work that involves team-wide coordination.

External modelers also bring varied experience from other pipelines, which sometimes leads to practical solutions that internal teams have not considered. Strong communication helps both sides avoid duplicated effort, and early alignment on deliverables prevents unnecessary revisions.

When everyone understands where the boundaries sit, outside specialists operate efficiently while the main team continues driving the larger production goals. Bottlenecks shrink because more hands carry the load, but without the overhead of new full-time hires.

Criteria for Selecting a Hard Surface Modeling Partner or Vendor

A capable vendor fits into an existing workflow with minimal disruption. Skill level is only one part of the evaluation; teams also assess how reliably the vendor interprets references, adheres to technical constraints, and communicates progress. A group that understands naming rules, topology expectations, and export standards will cause far fewer interruptions later.

Another factor is range: some vendors handle simple assets well but struggle with complex mechanical designs, while others maintain high consistency across different categories. Stability across multiple assignments reveals far more about quality than a single impressive sample.

Responsiveness also matters, since slow communication creates avoidable delays. A strong partner treats every handoff as a chance to reinforce trust rather than complicate the pipeline. When those qualities line up, external support blends naturally with internal production.

How Transparent Deliverables and Clear Specs Prevent Misalignment

Clear expectations remove most forms of confusion long before modeling begins. Teams work faster when every requirement, like scale, purpose, visual target, and technical limits, is stated plainly instead of left to interpretation. Detailed briefs shorten review cycles because both sides evaluate the asset against the same criteria.

Many issues arise when assumptions replace instructions, especially with measurements, naming conventions, or material structure. Providing example files helps external artists understand tone, density, and surface logic without guessing. Direct notes about export settings and validation rules also limit friction later.

Strong documentation keeps exchanges straightforward, and reviewers can focus on evaluating quality rather than explaining what should have been delivered. Transparent deliverables turn collaboration into a predictable workflow instead of a back-and-forth correction loop.

Best 3D Software for Hard Surface Modeling: Selection by Project Type

Different projects favor different tools, and choosing the right one often depends on how assets behave inside the broader pipeline. Some software excels at deformation control, others at rapid Boolean work or procedural generation. Teams frequently combine applications to cover gaps and keep production moving at a steady pace.

Understanding where each tool performs best helps avoid slowdowns, reduces cleanup, and keeps modeling decisions aligned with technical targets. A thoughtful selection process prevents mismatches that often appear when tools are chosen purely by habit rather than by need.

Autodesk Maya: Strengths, Limitations, and When Teams Prefer It

Maya appeals to teams that need strong deformation behavior, predictable rigs, and consistent geometry under animation. Many studios turn to it when hard surface assets must interact directly with articulated parts or simulation systems. The toolset supports a clean structure and an organized node history, which suits pipelines that emphasize technical stability.

Pivotal points that often influence Maya adoption include:

- Animation focus. Modeling integrates smoothly with rigging and simulation tasks.

- Structural control. Tools help maintain a clean topology for movement-dependent objects.

- Pipeline maturity. Many studios already rely on Maya for a large portion of their production.

- Slower exploration. Boolean work and rapid shape testing require more steps than in other tools.

Blender: Cost Efficiency, Feature Set, and Suitability for Scalable Asset Creation

Blender attracts teams that need flexibility and fast iteration without license constraints. Its modifier stack encourages non-destructive workflows, and the Boolean system handles complex shapes efficiently. Many modelers appreciate the viewport’s responsiveness and the ease of switching between sculpting, modeling, and shading modes.

Factors that make Blender practical for scalable modeling include:

- Modifier-driven edits. Rapid revisions stay reversible throughout production.

- Fast Booleans. Complex cuts resolve smoothly for mid-detail work.

- Accessible entry cost. Teams expand without facing expensive licensing.

- Viewport speed. Iteration feels immediate, which helps during early concept development.

3ds Max, Houdini, and Cinema 4D Compared for Structured Hard Surface Pipelines

3ds Max remains a dependable choice for traditional polygon work, mainly when teams rely on splines, chamfers, and familiar modeling conventions. Houdini stands apart with its procedural networks that automate repetitive tasks and generate variations at scale. Cinema 4D often fits into workflows that require fast previews, precise shading, and strong support for product- or motion-focused output. Each tool solves different production needs, so selection depends on volume, complexity, and the level of control required.

Let’s highlight the distinctions:

| Tool | Strength | Best Use Case |

| 3ds Max | Traditional modeling precision | Environments, props, architectural work |

| Houdini | Procedural control | Variations, automation, complex systems |

| Cinema 4D | Fast look development | Motion graphics, product visualization |

Each option offers strengths that matter in different contexts, so teams match the tool to workload rather than relying on a single universal solution.

Hard Surface Modeling in High-Value Projects with 3D-Ace

High-budget productions require modeling that stays accurate, predictable, and easy to integrate across many departments. Teams at 3D-Ace focus on building assets that support real engineering logic, stable shading, and efficient performance, which helps studios avoid repeated corrections.

Clients often choose our art outsourcing studio when they need reliable output for simulations, advanced training tools, or large content expansions. Every model follows clear standards that keep pipelines steady and maintain quality across long production cycles. Organizations that need detailed hard surface work can contact us to evaluate how our specialists handle complex requirements without slowing development.