We often highlight AI-driven solutions, innovative transportation methods, and captivating digital simulations when envisioning the technologies shaping our future. Despite the allure of these advancements, equally significant yet less visible technologies merit attention. Among these, digital twins (DTs) represent a crucial yet underappreciated innovation.

Presently, digital twin technology is employed across various nations, though it has yet to reach a level of ubiquity and application that renders it a common tool among businesses and individuals. Addressing this gap, our focus shifts to elucidating digital twins, encompassing their essence and detailing how to build a digital twin model.

Digital twins, in essence, are advanced virtual replicas of physical entities created to simulate real-world objects, processes, or systems. The process to create a digital twin involves meticulous data collection and analysis, enabling precise replication of the physical counterpart’s condition and behavior in a virtual environment. This capability makes digital twin technology indispensable across sectors like manufacturing, urban planning, and healthcare.

Employing 3D digital twin modeling services facilitates the creation of detailed, accurate virtual representations, enhancing decision-making and predictive analysis. The foundational step to create a digital twin model hinges on gathering comprehensive data about the physical object, including its dimensions, properties, and operational characteristics.

Understanding how to build a digital twin model involves more than replicating physical attributes; it requires integrating dynamic data that reflects real-time changes, ensuring the digital twin evolves alongside its physical counterpart. This dynamic modeling allows stakeholders to anticipate performance, optimize operations, and mitigate risks effectively.

Creating a digital twin model goes beyond mere replication; crafting a dynamic, interactive blueprint can predict future states, analyze potential scenarios, and provide actionable insights. To make a digital twin, it’s essential to leverage advanced modeling techniques that can accurately mirror the complexity of the physical world.

Building a digital twin model is a sophisticated process that blends detailed data collection with cutting-edge simulation technologies. This intricate procedure ensures that the digital twin serves as a valuable tool for analysis, prediction, and optimization across various applications.

What Is a Digital Twin and How Does It Work?

The concept behind a digital twin is straightforward: it serves as a virtual counterpart to a physical entity, mirroring everything from a tiny microchip to expansive areas like a football field. Envisioned as an exact 3D replica, a digital twin model replicates the characteristics, behaviors, and data of its physical counterpart, ensuring a high-fidelity representation.

Currently, the creation of digital twins predominantly targets sectors such as industrial manufacturing and architecture, where they depict inanimate objects. However, the potential to create a digital twin for living organisms, including plants and animals, exists, though its practical realization may still be on the horizon.

Digital twin models also find application in conceptualizing entities that have yet to be realized in the physical world. Serving as both a prototype and a test bed, they allow for the exploration and validation of new designs and concepts before they materialize.

Creating a digital twin involves a meticulous process of data collection and simulation to ensure the model accurately reflects its physical counterpart. This process is critical for industries looking to improve efficiency, predict performance outcomes, and streamline operations.

The utility of a digital twin model extends beyond mere replication, offering insights into performance optimization, potential failure points, and maintenance needs. By learning how to build a digital twin model, organizations can make informed decisions, enhancing product development and operational efficiency.

To build a digital twin model, one must gather detailed information about the physical object’s properties and operational dynamics. This foundational step is crucial for creating a model that not only mirrors the physical object but also evolves with it over time.

In essence, the ability to create a digital twin opens up new avenues for innovation and problem-solving across various fields. Through the precise replication and simulation of physical entities, digital twin technology paves the way for advanced analysis and predictive modeling, transforming how we interact with both the physical and virtual environments.

How digital twins work

Once developed, digital twins solutions retain the appearance, characteristics, and functionality of their physical counterparts, enabling activities that might be impractical or risky with the actual object. For instance, executing simulations within a digital twin model allows for the assessment of an object’s performance or the evaluation of minor process modifications on overall functionality. Essentially, this approach facilitates the acquisition of fresh, precise data from the digital twin, data that would be significantly more challenging to obtain from the physical entity.

Employing a digital twin model to conduct experiments offers a safe and controlled environment to test hypotheses and make adjustments without the constraints or potential hazards associated with physical testing. The capacity to create a digital twin and utilize it for such analyses underscores the value of this technology in refining and optimizing operational processes.

The process to create a digital twin encompasses the replication of the physical object’s every nuance, ensuring that the model serves as an accurate virtual mirror. This meticulous replication is crucial for the reliability of the data generated from simulations and tests conducted on the digital twin.

Creating a digital twin model goes beyond mere visual or structural mimicry; it involves the integration of real-time data and analytics to mirror the object’s life cycle dynamically. This dynamic modeling makes it possible to predict future conditions, assess potential impacts of changes, and derive actionable insights.

To build a digital twin model, it’s essential to gather comprehensive data about the physical object, including its design specifications, operational data, and environmental interactions. This foundational step is pivotal in how to build a digital twin model that accurately reflects its physical counterpart.

Through the creation of a digital twin, stakeholders can simulate scenarios, predict outcomes, and make informed decisions with a level of detail and accuracy that traditional physical testing methods cannot match. This innovative approach not only enhances understanding and optimization of existing systems but also paves the way for the development of new solutions.

Benefits

The testing capabilities of digital twins stand out as a primary advantage. An accurate digital twin model allows for the digital application of changes to predict outcomes on the actual model. Utilizing advanced software for this purpose accelerates the process, eliminating risks associated with physical models.

Prototyping benefits significantly from the digital twin approach. By first constructing a digital model before embarking on actual construction, designers gain the ability to refine designs and ensure reliability without the constraints of physical prototyping. The process to create a digital twin using 3D data simplifies the initial stages of design, offering a clear advantage over traditional measurement and modeling techniques.

Numerous enterprises adopt digital twins to enhance business operations, finding them invaluable for tasks like remote technical troubleshooting. When digital twins are integrated with Product Lifecycle Management (PLM), Enterprise Resource Planning (ERP), and Enterprise Asset Management (EAM) systems, they significantly elevate production efficiency.

Types of Digital Twins

Though there is no official classification of DTs accepted by scholars, we can point out a useful grouping often used in manufacturing:

Component Twin

The concept of a digital twin primarily focuses on an individual component, frequently a part of a more extensive system or device. Consider a scenario where a company is developing a new sprocket for their engine or evaluating an existing one; they might create a digital twin to accurately determine its rotational speed, structural integrity, design optimization, and material suitability for expected tasks.

Creating a digital twin allows for detailed analysis and simulation, offering insights into how the component performs under various conditions without the physical wear and potential risks. This precise modeling aids in fine-tuning the sprocket’s specifications before it becomes a tangible part of the machinery, ensuring its efficiency and durability in real-world applications.

Asset Twin

A digital twin is often crafted for a singular entity composed of numerous internal parts, such as a motor, television, traffic light, or fishing rod. While this digital twin model may incorporate component twins (CTs), the emphasis shifts from the minutiae of individual components to the functionality of the entire object and its interaction with the various parts. This approach represents the prevalent form of digital twin usage, with countless companies creating digital models of their products, perhaps unaware of the formal classification and the potential for expansion these models hold.

To create a digital twin of such a complex system requires a comprehensive approach, focusing not only on the assembly of parts but on how these components coalesce to form a functional whole. Learning how to build a digital twin model encompasses understanding both the macro and micro perspectives, ensuring that every facet of the object is replicated accurately for analysis and improvement. This method allows for a holistic view, making it possible to optimize the object’s overall performance and reliability.

System Twin

The system-type digital twin encapsulates an entire operational ecosystem comprising multiple assets, each with distinct components. This comprehensive digital twin model allows for the analysis of how effectively the system operates as a unified entity while also offering the flexibility to inspect the performance of individual assets and their components within the system’s framework. For instance, such a digital twin can depict a manufacturing conveyor belt system, the integrated machinery in an automatic car wash, or an entire building, complete with its various floors and utilities.

To create a digital twin of this nature involves synthesizing a complex network of interconnected components into a cohesive model that accurately reflects the system’s dynamics. Learning how to build a digital twin model of a system demands a deep understanding of both the individual elements and their interactions, ensuring a holistic representation that can be used to enhance system efficiency and diagnose potential issues.

Process Twin

Every process type digital twin aims to simulate and illustrate comprehensive procedures, whether they encompass multiple systems collaborating or a singular object executing a specific task. The scope of such a digital twin model can significantly vary. For instance, within the manufacturing sector, creating a digital twin involves incorporating data from each phase of the production cycle, encompassing the receipt of raw materials, their conversion, shaping, coloring, packaging, and eventual distribution. Primarily, these digital twins are deployed to enhance large-scale business operations, offering substantial support to Product Lifecycle Management (PLM) systems.

Ever wondered how to create a digital twin? To create a digital twin of a process involves a detailed mapping and replication of every step within the system, ensuring a precise model that can predict outcomes, identify inefficiencies, and suggest improvements. Building a digital twin model for process optimization not only facilitates a deeper understanding of the entire operation but also enables the identification of potential enhancements at every stage. This holistic approach to creating digital twins serves as a catalyst for refining business processes, making them more efficient and effective.

How Digital Twins Are Made

The process of building DTs is complex and very difficult to master in a limited amount of time, but it can be broken down into 4 basic stages.

Step 1 – Planning

Before initiating the development of such a solution, whether doing it yourself or seeking external expertise, it’s imperative to have a firm grasp on the desired outcomes. Question if the purpose is to serve as an ultra-detailed display for your product or act as a critical tool for identifying and solving issues. Consider if you aim to utilize the tool for crafting theoretical scenarios or if its main role will be to relay current data from its physical equivalent. These inquiries are essential during the planning phase to ensure a definitive understanding of the digital twin’s purpose, the data it will encompass, and the level of accuracy you seek.

Embarking on the journey to create a digital twin involves strategic planning to outline its goals, whether for an intricate product demonstration or as a diagnostic resource. Determining if the tool should enable the creation of hypothetical situations or focus on mirroring live data from the actual object is crucial. Addressing these considerations at the outset helps to define a clear direction for the digital twin, guiding the choice of data and desired precision level. This preliminary step is key in developing a digital twin model that effectively meets specific operational or demonstrative needs.

Step 2 – Measurements

Creating a digital twin as a prototype for an object not yet in existence offers the flexibility to define its parameters and performance for the virtual product. In contrast, replicating an existing object demands precise data and measurements for the digital twin model to function correctly. These requirements range from straightforward tasks, such as documenting an object’s dimensions, to more intricate processes involving sensors.

For instance, deploying movement sensors on various components of a manufacturing line can capture detailed information about equipment behavior — speed, force, position, and precision during production. Additionally, visual documentation through photographs and scans plays a crucial role in refining the digital twin model for subsequent development phases.

To create a digital twin with accuracy, especially for current assets, involves gathering comprehensive data, including physical dimensions and dynamic operational data, to inform the digital model. When the aim is to build a digital twin for hypothetical products, designers have the liberty to specify desired attributes without the constraints of existing templates.

This foundational data collection, whether simple or complex, is essential for crafting a digital twin that mirrors the real or envisioned product with fidelity. Visual resources further enhance the model’s development, ensuring the digital twin provides a faithful and functional representation of the physical or conceptual product.

Step 3 – Generation

To create a dynamic and adaptive digital twin, initiating its development within a software environment is essential. This setting provides a platform for examination and modification post-creation. The visual aspects of the intended target can be crafted using specialized modeling software, whereas the performance and functional attributes necessitate a comprehensive virtual testing ground.

Options for housing your digital twin include developing a bespoke application or opting for existing platforms designed for such purposes, such as Predix or Seebo. The data gathered earlier is then integrated into the software dedicated to modeling, visualization, coding, or twinning, culminating in the virtual solution envisioned. This process transforms raw data into a functional digital twin model, bridging the gap between theoretical design and practical application.

Creating a digital twin involves meticulous planning and execution, where the choice of platform can significantly influence the project’s trajectory. Whether building from the ground up or leveraging existing software, the objective remains to make a digital twin that meets the envisioned criteria, offering insights and optimizations for the physical counterpart it represents.

Step 4 – Operation

Upon activating your digital twin, immediate refinements often become a priority. The data-centric nature of your solution enables rapid identification of problems, allowing for swift modifications to rectify any issues. Occasionally, the challenges encountered may originate from the software rather than the physical components or objects it represents. In such instances, implementing tweaks, correcting bugs, and rewriting code become necessary actions. Once the pressing concerns are addressed, the digital twin model becomes a valuable asset for continuous testing, analysis, and enhancement.

Activating a digital twin sets the stage for initial adjustments based on its performance feedback. If the solution is heavily reliant on data, pinpointing and resolving issues can occur quickly. Should the software itself be the source of the problem, comprehensive adjustments, including bug fixes and code optimization, are essential. After resolving these initial issues, the digital twin serves as a dynamic tool for ongoing optimization, enabling detailed scrutiny and incremental improvements to the system it mirrors.

Examples of Innovative Digital Twins

Although digital twins haven’t become mainstream with widespread acceptance across numerous companies, a substantial number of compelling use cases have emerged, demonstrating their significant impact and inspirational capabilities. From optimizing manufacturing workflows to enhancing urban development, creating a digital twin offers unparalleled insights and operational efficiencies.

Consider the manufacturing sector, where deploying a digital twin model facilitates the simulation and analysis of production lines. This method allows businesses to anticipate maintenance needs, streamline operations, and significantly reduce unplanned downtime. The precision in creating these models enables a closer look at the intricacies of manufacturing processes.

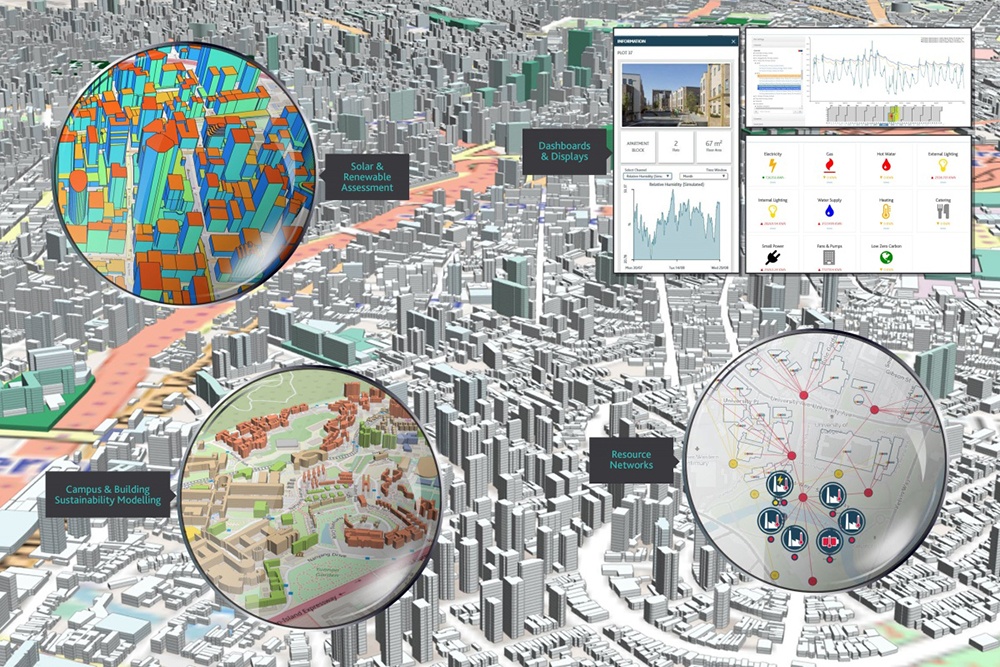

Urban development benefits from digital twins through advanced planning and sustainability practices. Architects and city planners create digital twin models of buildings and urban areas to assess the environmental impact, optimize energy usage, and improve residents’ quality of life. This innovative approach transforms the planning and development phases, ensuring more resilient and sustainable urban environments.

The healthcare industry utilizes digital twin technology to model hospital operations or simulate patient care pathways, enhancing efficiency and patient outcomes. Creating a digital twin of a healthcare facility enables administrators to optimize workflows, resource allocation, and emergency responses, ultimately elevating the standard of care provided.

Environmental conservation efforts are bolstered by the ability to model ecosystems or resources, aiding in sustainable management decisions. Through such simulations, environmental scientists can predict the outcomes of conservation strategies, making well-informed choices that protect natural habitats while supporting human activity.

Product development also sees advancements through digital twins, with companies creating detailed models of new products to test and refine before physical production begins. This strategy reduces development costs, shortens time-to-market, and ensures a higher quality final product.

The City Twin

We have mentioned DTs the size of football fields, but some people think even bigger. The residents of Herrenberg in Germany have built a one-of-a-kind virtual model of their town using this innovative software. The virtual city includes features to monitor traffic flows, wind and emissions, as well as make informed choices about construction projects in this region.

In addition, there is a feedback feature allowing residents to share information relevant to other dwellers of the town. This approach has the potential to help city planners make meaningful changes to the locality and for residents to enjoy them.

Finding new cures

2 major companies (Atos and Siemens) are partnering to build a solution that could transform the pharmaceutical industry as we know it. They are working on a DT of the “Process” type which can be applied to develop new medicines and pharmaceutical products.

As you probably know, the development of drugs, vaccines, and medicinal compounds is a long process fraught with numerous challenges, but this new initiative seeks to speed up parts of the process. Their solution is driven by predictive modeling and data crunching, and designed to reduce waste in the industry, whether it refers to physical materials or fruitless experimentation.

Voyages made warmer

Marine vessels and ships have complex heating systems that use up a lot of their energy and fuel, and unfortunately, much of the heat goes to waste due to inefficiency. To tackle this issue, researchers from the Lappeenranta University of Technology have embarked on a project to improve vessel heat efficiency through DTs. They have built a real waste heat recovery unit and proceeded to create a DT of it. If all goes according to plan, this tool can be utilized by ship operators to make their vessels run more efficiently and stay warmer in cold sailing conditions.

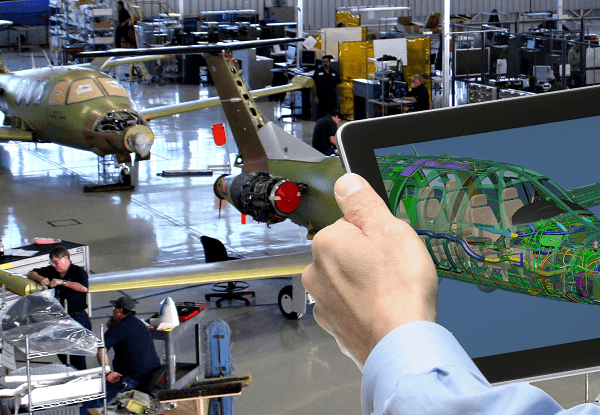

Giving new life to old military hardware

Source: Design News

The U.S. Army is working closely with Wichita State University to build a twin of their famed Black Hawk helicopter. This helicopter entered service more than 40 years ago and was eventually replaced by newer models, but the army still has a fleet of these helicopters that it wants to operate, and this requires proper maintenance. Thus, DTs of the helicopter and its hundreds of components will make it much easier for the Army to replace faulty parts and conduct repairs, thus prolonging the lifespan of the legendary aircraft.

Digital Twin Services

Given the complexity of digital twin model creation, you will likely need several development partners if you opt to build anything of this kind. There are multiple businesses that specialize in building solutions for digital twins, and 3D-Ace is among them.

Our studio boasts a rich history of crafting high-quality digital twin models, a journey that has endowed us with extensive experience and diversified our expertise. Dedicated to generating both 2D and 3D content, we excel in producing game models, animations, visual effects, and industry-specific solutions such as walkthroughs and visualizations. Within the scope of digital twins, we are equipped to create assets and visualizations that form the core graphical elements of your model, ensuring seamless integration into existing business systems like ERP, PLM, EAM, among others.

We know how to make a digital twin tailored for your specific business. The ability to create a digital twin encompasses more than just the creation of intricate models; it involves a deep understanding of how to bring these models to life within your operational ecosystem. Our proficiency lies not only in our capacity to build detailed and accurate digital twin models but also in our skill to make these models interact dynamically with critical business systems, enhancing efficiency and insight.

Our commitment extends beyond merely creating digital twin models; we strive to ensure that each digital twin we develop becomes a vital part of our clients’ operational processes. By integrating the digital twin seamlessly with systems such as ERP, PLM, and EAM, we unlock new dimensions of functionality and utility, transforming these models from mere representations into indispensable tools for business innovation and growth.

We find DT technology fascinating, and our specialists are always eager for new projects that will let them do what they do best — visualize. If you want to know more about our services and how we could cooperate, reach out to us at any convenient time.