People started to talk about the 3D printing technology about ten years ago and soon after the first printer prototypes have been released. Today, it’s not a surprise that the industry is developing and trying to push itself to mass consumption. Compared to other technical branches, it’s still quite a small business. However, it possesses a huge potential. Today, 3D-Ace would like to study the 3D printing industry and find out what distinguishes it from others, what challenges it meets and what we can expect in the future.

3D printing Technology Overview

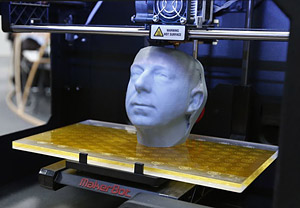

Firstly, we want to talk a little about existing manufactures and their experience. Some enthusiasts organised the so-known open-source initiative. The most well-known initiative is The RepRap (Replicating Rapid Prototyper) hardware project. The point of which is to produce and improve low-cost printers that use fused filament fabrication (FFF) technology. FFF involves the creation of three-dimensional objects by applying successive layers of material that follow the contours of the digital model. As a rule, thermoplastics in the form of spool of filaments are used as the material to perform printing. Although the FFF printers are considered to be inexpensive, however, some of them can have a price similar to the price of your house. Printers based on the RepRap technology still occupy a big part of the market. In fact, some private companies adopt and adapt some of RepRap specifications in order to be compatible with other industry technologies.

Firstly, we want to talk a little about existing manufactures and their experience. Some enthusiasts organised the so-known open-source initiative. The most well-known initiative is The RepRap (Replicating Rapid Prototyper) hardware project. The point of which is to produce and improve low-cost printers that use fused filament fabrication (FFF) technology. FFF involves the creation of three-dimensional objects by applying successive layers of material that follow the contours of the digital model. As a rule, thermoplastics in the form of spool of filaments are used as the material to perform printing. Although the FFF printers are considered to be inexpensive, however, some of them can have a price similar to the price of your house. Printers based on the RepRap technology still occupy a big part of the market. In fact, some private companies adopt and adapt some of RepRap specifications in order to be compatible with other industry technologies.

On the other hand, RepRap machinery is restricted to the triple-F technology which is common, however, limited and cannot be used in many branches of business.

There are other widely-used technologies at the market. For instance, granular printers use a laser to heat a powdered metal to melt the necessary object. Another example is stereolithography printers that work with liquid substances and transform them into a solid object using light. The very last printers possess a number of benefits before others in terms of precisions and efficiency, however, they have a narrow list of possible materials and cannot be used to produce metal or food.

Challenges of 3D printing

After reading the last line and realising that you can get food on the output of 3D printers like pasta or chocolate, you probably thinking about why we still don’t have such printers at home or office. Well, this technology is facing some difficulties and obstacles on the way to becoming widely-used. The following challenges and issues slow the development process:

Extremely expensive equipment

Most people compare 3D printers to regular paper-based printers and wonder why they can’t use them. Well, first of all, of course, technology is moving forward, and thanks to that fact 3D hardware becoming cheaper and cheaper. However, for many potential consumers, the price is still remarkably high. Besides, 3D printers require a lot of maintenance and operating personnel to print three-dimensional object.

Narrow target audience

Compared to the traditional laser printers that have an enormous consumer base, 3D printers are focused on a smaller group of people, primarily because of the high-priced equipment and the complexity of maintenance.

Not developed technologies

Despite the fact that 3D printing area has been introduced to the world a couple of years ago, it’s still an undeveloped industry. However, it is a concentration of innovations and possesses a great potential.

Speed & sensibility

3D printers are quite slow and extremely responsive to negative conditions.

Low ROI index

This is, probably, the main reason why businesses aren’t willing to purchase 3D printers (at least yet). These devices cannot be compared with regular manufacturers in terms of energy efficiency, price, maintaining costs and rate of working.

However, the industry of 3D printing is developing at the high rate and soon we can expect our familiar manufactured items to be replaced with 3D printed things.

3D Printing Services

If you have an idea in your head that is in developing or image of some device or a product and cannot understand is it profitable to produce it, you just need a little clues. For that purpose, you should see the prototype, test it and make sure everything will work. So tell us, would you rather buy a necessary printer or to find someone who provides 3D printing services?

Such service is a great opportunity for many small businesses or single developers explore the upsides of 3D printing without spending a fortune. On our professional opinion, this is a good direction where the whole industry should move. Now, let’s talk about the necessary things that you need to get ready before printing.

First of all, you should have an idea of the prototype you are going to print. Make sure your idea is worth attention and need to be printed, then visualise every detail of your future model, make a sketch to be sure that everything is well-documented. Second, you will need to design this object using appropriate 3D tool. Artists work with various software or modeling programs such as 3ds Max, Blender, SketchUp, ZBrush or SolidWorks that allows developing of three-dimensional model that, basically, will be a physical reflection of your sketch.

Brief 3D modeling Guideline

Since 3D printers reproduce the model literally by expansion it into layers, the structure of your model should follow generally accepted rules, otherwise the printer won’t be able to proceed it in the correct way. The main requirement to the model is that it should be built in XYZ-coordinates since printbeds shift along these axes. Besides, if your model is not solid and has holes or openings you need to take it into consideration and make the necessary adjustments or involve different one-off material that can be eliminated after the printing stage. In addition, there are also some size limitations that depend on a type of 3D printer. You will need to present a model that can comply with a certain printer size and volume.

The 3D printing industry is just in its preparatory development stage. Every day it introduces new inventions, improvements and enhancements of the technologies or development process. It should be said that modeling software can be costly to purchase and hard to comprehend, especially if you’re new in the field or have a one-time need to create a model. In that case, it’s a good idea to hire experts who can implement your ideas and create a model within requirements and specification. 3D-Ace provides its clients with professional modeling services for 3D printing. Our 3D artists create incredible models and help clients to extend their conception about technology advantages.

The Perspectives of 3D Printing

Many people consider 3D printing to be a revolutionary technology that will change our idea of manufacturing. Although it possesses huge potential, it’s still too immature to cause industry revolution. However, it’s definitely a branch of technology you should pay attention to, as well as invest money on its development. In the future, we will be able to watch the significant growth in business models and the technology implemented in 3D printing, even though today it doesn’t seem so. Still we will see the progress thanks to new use cases and modifications. A lot of attention will be devoted to the full-circle services which mean that businesses can work with third-party companies in order to receive qualified 3D printing services without purchasing a bunch of 3D printers.

3D-Ace and 3D printing

The 3D-Ace team suggests that 3D printing is a dynamically developing industry that will soon become a leading technology. Ipso facto, our professional experts are ready to help you get qualified assistance in modeling for 3D printers. We have huge experience in using efficient modeling techniques and software and can implement any your idea in a 3D world.